What Does Plied Mean in Yarn? Understanding Structure, Benefits & Uses

In the world of yarn and textile manufacturing, structure matters just as much as fiber content. One essential term you’ll often encounter is “plied yarn.” But what exactly does plied mean in yarn, and why is it so widely used across both industrial and handcraft applications?

In this article, we’ll demystify plied yarn—what it is, how it’s made, its advantages, popular types, and how it compares to single-ply yarns. Whether you’re a textile manufacturer, designer, or hobbyist, understanding plied yarn can help you make better choices in your yarn sourcing or creative projects.

What Is Plied Yarn?

Plied yarn, also known as “folded yarn,” is created by twisting together two or more individual strands of yarn—called singles—into a thicker, more structured composite yarn. This process, known as plying, helps to enhance the yarn’s strength, balance, durability, and texture.

For example, a 2-ply yarn means two single yarns have been twisted together. You might also see 3-ply, 4-ply, or even 6-ply yarns in industrial applications or high-strength textile products. The twist direction and ply count can significantly affect the yarn’s characteristics.

In manufacturing, plying is done using ring doubling frames or cable twisters to ensure controlled tension and consistent twist. In handcraft settings, plying can be done with a spinning wheel or drop spindle.

Blending is typically done before or during spinning, and the ratio of fibers can vary depending on the performance, texture, and price point the manufacturer wants to achieve.

Why Is Yarn Plied?

Plying is more than a technical step in production—it transforms how the yarn performs. Here are the primary reasons manufacturers and artisans use plied yarn:

1. Improved Strength & Durability

Plied yarns are typically stronger than single-ply equivalents because the multiple strands support each other, reducing breakage. This is crucial for garments and textiles that undergo frequent use or washing.

2. Balanced Twist

Single yarns can have a natural bias or curl due to the twist direction. Plying counteracts this by combining opposing twist directions (usually S-twist + Z-twist), resulting in a more stable and balanced yarn. This balance prevents fabric distortion during knitting or weaving.

3. Enhanced Appearance & Texture

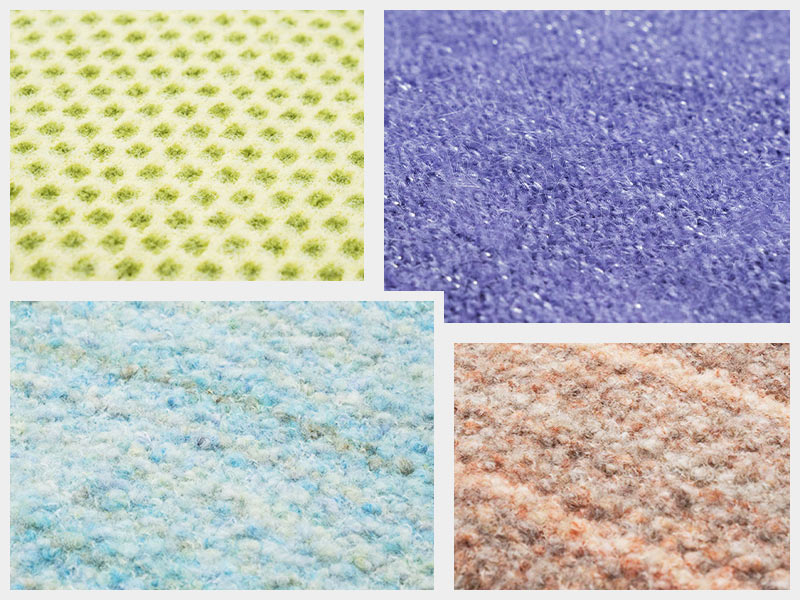

Plying can add visual interest and dimension. Multi-colored or marled plied yarns are popular in fashion textiles and hand knitting for their unique surface textures. Plying also creates a rounder yarn cross-section, leading to better stitch definition in knitted items.

4. Reduced Pilling

Since plied yarns are denser and more compact, they are less likely to shed or pill, extending the life of the finished fabric. This makes plied yarn ideal for workwear, uniforms, and other heavy-duty applications.

5. Greater Design Control

From smooth, fine threads to bulky novelty yarns with loops and coils, plying offers designers a way to control thickness, texture, and behavior of the yarn in various applications. Different ply techniques, such as cable plying or core spinning, can also enhance performance or visual aesthetics.

Types of Plied Yarn

Depending on the desired result, plied yarns can take many forms. Some of the most common types include:

Ply Type | Structure | Common Uses |

2-ply yarn | Two singles twisted together | Knitting, weaving, embroidery |

3-ply yarn | Three singles twisted for extra roundness | High-end sweaters, socks, outerwear |

Cable yarn | Plied yarns twisted again into a thicker yarn | Industrial fabrics, workwear |

Marl yarn | Plied yarn made from different-colored singles | Fashion garments, novelty textiles |

Fancy plied yarn | Irregular textures like boucle or slub | Decorative fabrics, scarves, upholstery |

Core-spun plied yarn | Fiber wrapped around a filament or core | Durable, high-stretch applications |

Tip: Higher ply counts don’t always mean thicker yarn. Fineness and twist tension also play a role. Some fine 6-ply yarns are thinner than coarse 2-ply yarns.

Applications of Plied Yarn

Plied yarn is widely used across a range of industries due to its balanced properties and adaptability. Some of the top applications include:

Apparel Manufacturing

From basics to high fashion, plied yarns are used in sweaters, socks, gloves, and woven shirtings. The structure ensures comfort, shape retention, and long-term wearability.

Home Textiles

Blankets, cushion covers, curtains, and upholstery fabrics often utilize plied yarns for added durability and aesthetic appeal. Fancy plied yarns can add texture or contrast to home décor collections.

Technical Textiles

Cable yarns and high-ply constructions are used in ropes, seatbelts, belts, filters, and fire-retardant fabrics where mechanical strength, abrasion resistance, or thermal properties are important.

Hand Knitting & Crochet

Knitters and crocheters favor plied yarns for their stitch definition, elasticity, and smooth handling. Whether it’s for garments, accessories, or amigurumi, plied yarns offer control and quality.

Weaving & Embroidery

Because of their even diameter and strength, plied yarns are preferred for warps in weaving or for detailed, structured embroidery work.

Plied Yarn vs. Single Ply Yarn: What’s the Difference?

Understanding the differences between plied and single-ply yarn helps in selecting the right material:

Feature | Plied Yarn | Single Ply Yarn |

Structure | Multiple strands twisted together | One continuous strand |

Strength | Stronger, more durable | Weaker, more prone to stretching |

Balance | More stable and even | Can be biased or twist unevenly |

Appearance | Rounder, smoother | Flatter, fuzzier |

Texture | Firm and dense | Soft and lofty |

Use Cases | Garments, accessories, technical fabrics | Soft knits, felting, artistic textures |

Single-ply yarns, while beautiful and soft, are generally better suited for delicate projects or intentional texture effects, whereas plied yarns are more versatile and durable.

How Is Plied Yarn Made?

The process of creating plied yarn typically involves the following stages:

Spinning: Individual fibers are spun into single strands.

Twisting (Plying): Two or more singles are twisted together in the opposite direction to the spinning twist.

Winding & Finishing: The plied yarn is conditioned, sometimes heat-set, dyed, or wound into cones or skeins.

Advanced plying techniques like core spinning, chain plying, or reverse plying can produce functional or decorative yarns for specific market segments.

Our Plied Yarn Collection

At Duoyou Yarn, we offer a wide array of plied yarns designed to meet the needs of global textile manufacturers, designers, and crafters. Our product range includes:

Classic Plied Yarns: For fashion, socks, flat knitting, and weaving

Fancy Plied Yarns: Including slub, loop, knot, marl, and space-dyed effects

Technical Plied Yarns: For high-performance applications like workwear and industrial use

Eco-Friendly Options: Recycled polyester-cotton plied yarns, biodegradable blends, and more

Explore Our Plied Yarn Collection

Contact Us for Samples or Custom Orders

Conclusion

Plied yarn stands as a fundamental yet versatile element in the textile world. Its unique construction not only enhances strength and stability but also opens up countless aesthetic and functional possibilities. Whether you’re creating a durable fabric, an expressive garment, or a technical textile, plied yarn delivers a balance of performance, design, and creativity.

Related News

Discover more about the latest developments in the yarn industry, explore articles on development trends and innovative technologies, and provide you with more industry insights.

Is Slub Yarn Better for Summer or Winter? Textile Brands: Uses, Benefits, and Seasonal Tips

In modern fashion and textile manufacturing, slub yarn is one of the most popular types of yarn. The slightly uneven thickness of the fabric gives it a natural, handmade look that fits in with current fashion trends. But one question that designers, yarn buyers, and manufacturers often ask is whether slub yarn is better for summer or winter.

Guide to Use Chrysanthemum Yarn for Commercial Knitwear

In the global knitwear market, texture has become one of the most effective ways to differentiate products. Buyers are no longer impressed by basic yarn descriptions such as “soft,” “bulky,” or “hairy.” What really drives B2B purchasing decisions today is whether a yarn can deliver visible texture, stable production performance, and repeatable quality at scale.This is exactly where Chrysanthemum Yarn stands out.

Blended yarns are very important in the modern textile industry because they let you combine the best parts of different fibers while getting rid of their worst parts. When you spin two or more types of fiber together, like cotton with polyester, wool with nylon, or cotton with spandex, you get a blended yarn. This type of yarn has properties that aren’t found in single-fiber yarns.