Toothbrush Yarn Manufacturer Guide | Fancy Yarn Solutions for Fashion & Home Textiles

The world of fancy yarns is constantly evolving, with new innovations pushing the boundaries of fabric aesthetics and texture. Among these innovations, toothbrush yarn stands out due to its unique spiky texture, three-dimensional volume, and bold visual appeal. As fashion and textile designers search for materials that offer both function and form, toothbrush yarn is rapidly gaining attention as a versatile and modern solution.

But what exactly is toothbrush yarn? How is it made? What sets it apart from other fancy yarns in the market? And why is it becoming so popular across industries ranging from fashion to interior design? In this blog, we will explore the answers to all these questions and more.

1. What is Toothbrush Yarn?

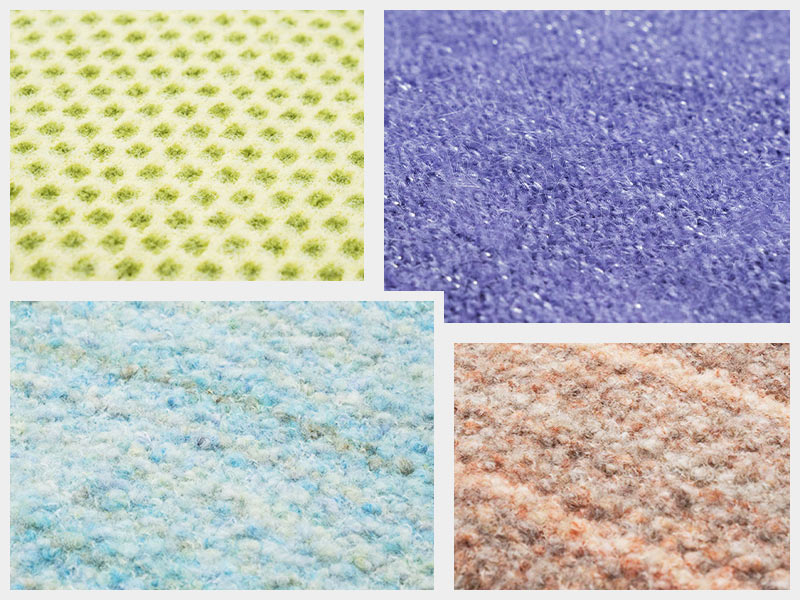

Toothbrush yarn is a type of fancy yarn characterized by its bristle-like surface, which resembles the appearance of a toothbrush. It features numerous short fibers that stick out perpendicularly from a core yarn, creating a spiky, three-dimensional effect that makes the yarn visually striking and texturally rich.

Blending is typically done before or during spinning, and the ratio of fibers can vary depending on the performance, texture, and price point the manufacturer wants to achieve.

This structure provides not only a unique aesthetic but also interesting tactile properties. Depending on the fiber composition and tuft density, toothbrush yarn can feel fluffy, springy, soft, or even firm. This versatility makes it suitable for a wide range of textile applications—from statement fashion pieces to plush home décor items.

2. The Structure of Toothbrush Yarn

To understand toothbrush yarn, it’s important to break down its physical structure:

Core Yarn: Usually a filament yarn (polyester or nylon) that provides strength and elasticity.

Tuft Fibers: Short fibers or loops that are inserted into or wrapped around the core yarn to create the spiky “bristle” effect.

Spacing and Orientation: The tufts are arranged in consistent spacing and direction, typically perpendicular to the yarn axis, which creates a uniform and voluminous effect.

These three structural elements work together to create a yarn that is both durable and decorative.

3. How is Toothbrush Yarn Produced?

The production of toothbrush yarn involves specialized machinery and techniques not typically used in standard spinning or twisting processes. The manufacturing generally follows these steps:

These three structural elements work together to create a yarn that is both durable and decorative.

a. Raw Material Selection

Core Yarn: Polyester, nylon, or elastic filament is selected for its strength and durability.

Effect Fiber: Polyester, acrylic, viscose, metallic yarns, or even specialty blends are chosen for the tufts.

The raw material choice impacts the softness, resilience, and luster of the final yarn.

b. Crochet or Warp-Knitting Machine

Toothbrush yarn is typically made on a crochet knitting machine 。This machine allows fiber tufts to be inserted into a chain of loops formed by the base yarn.

Each needle picks up a loop of the effect fiber and locks it into the knitted base.

The fiber loops or tufts protrude vertically from the base chain, forming the distinctive “bristle” appearance.

c. Loop Cutting (Optional)

In some versions, the loops are cut after formation, resulting in a sharper, more rigid bristle-like texture. This technique can be adjusted depending on the desired yarn hand feel and final application.

d. Heat Setting and Winding

Once the yarn structure is stabilized, heat setting may be applied to lock in the tuft positions and improve dimensional stability. The yarn is then wound onto cones or bobbins for packaging.

This process offers excellent flexibility in terms of color, fiber type, tuft length, density, and texture.

4. Characteristics of Toothbrush Yarn

Toothbrush yarn possesses several distinctive characteristics that make it stand out in the realm of fancy yarns:

3D Texture: With tufts protruding from the core, it creates a highly dimensional surface.

Visual Impact: The yarn adds drama and movement to otherwise flat fabrics.

Soft to Firm Touch: Depending on fiber type and tuft cut, it can feel plush or crisp.

Customizable: Colors, tuft lengths, spacing, and core compositions are easily modified.

Durable: With a strong core yarn, it holds its shape well under tension.

Color Play: Multi-color tuft effects are possible, enhancing visual complexity.

These properties make toothbrush yarn a favorite among designers seeking impactful textures.

5. Toothbrush Yarn vs. Other Fancy Yarns

Fancy yarns come in many forms—slub yarn, boucle yarn, feather yarn, chenille yarn, air yarn, and more. Here’s how toothbrush yarn compares:

Yarn Type | Appearance | Texture | Structure | Best For |

Toothbrush Yarn | Spiky, tufted | Fluffy or firm | Core + upright tufts | Fashion, upholstery, accents |

Chenille Yarn | Velvety | Soft, plush | Short pile twisted on a core | Sweaters, blankets |

Feather Yarn | Feathery | Light, airy | Flat, fringed loops | Shawls, scarves |

Air Yarn | Hairy | Soft, fuzzy | Blown fibers onto the core | Knitwear, blankets |

Slub Yarn | Uneven | Bumpy | Thick-thin sections | Rustic styles |

Loop Yarn | Curled | Stretchy, soft | Continuous loops | Cushions, décor |

Among them, toothbrush yarn delivers the most defined three-dimensionality, creating bold textural effects.

6. Applications of Toothbrush Yarn

Toothbrush yarn is highly versatile and used in a wide variety of applications. Its unique aesthetic makes it particularly valuable in the following areas:

a. Fashion and Garments

Outerwear: Jackets, coats, and parkas with bold trims or panels.

Sweaters and Pullovers: For fluffy, voluminous looks.

Fashion Accessories: Scarves, hats, gloves, and wraps.

b. Functional Use

Cleaning Mitts and Cloths: Tufts can provide mild abrasion.

Decorative Trims: For costume design or festival wear.

7. Design Customization Options

One of the most exciting aspects of toothbrush yarn is the flexibility it offers to product developers:

Tuft Lengths: Vary from 3mm to 20mm depending on the effect.

Tuft Density: High-density tufting results in a fuller appearance.

Color Effects: Solid, space-dyed, or multi-tone tufts can be combined with colored core yarns.

Core Compositions: Use elastic cores for stretch effects or rigid cores for structure.

Finish Options: Soft-touch, matte, glossy, or even metallic tufts.

Textile designers can use these variables to control not only the yarn’s aesthetic but also the drape, stretch, and durability of the fabric.

8. Toothbrush Yarn Specifications

Toothbrush yarn is generally specified using the following parameters:

Count Range:custom available

Core Yarn: 100% polyester, 100% nylon, or spandex blends

Tuft Fiber: Polyester, acrylic, viscose, metallic

Color Options: Customized

MOQ: May vary based on color or tuft customization

Suppliers may also provide technical data such as elongation rate, shrinkage, and yarn strength for manufacturing reference.

9. Challenges in Production and Fabrication

Despite its advantages, toothbrush yarn does come with certain challenges:

a. Machinery Compatibility

Not all circular knitting or weaving machines can easily accommodate the bulk of toothbrush yarn. Gauge adjustments or special needles may be required.

b. Tension Control

Improper tension can cause irregular tuft distribution or flattening during knitting.

c. Yarn Waste

Due to the structural complexity, toothbrush yarn may generate slightly more production waste compared to standard fancy yarns.

d. Dyeing Uniformity

For tuft fibers and core yarns of different materials, achieving even dye uptake requires technical expertise.

Working closely with experienced yarn producers can help address these challenges effectively.

10. Tips for Choosing the Right Toothbrush Yarn

If you’re considering toothbrush yarn for your next project, here are some tips:

Always Request Samples: Ensure the tuft density and hand feel match your expectations.

Clarify Fabric Usage: Inform the supplier about your end application so they can recommend suitable yarn specs.

Discuss MOQ Early: Some customized colorways or tuft lengths require higher order minimums.

Check Wash and Wear Properties: Especially if the product is for apparel or upholstery use.

Plan for Bulk Consistency: Confirm colorfastness, tuft stability, and repeatability with your supplier.

11. Who Should Use Toothbrush Yarn?

Toothbrush yarn is ideal for:

Fashion Designers who want to add bold texture.

Textile Manufacturers looking to innovate in premium home textile collections.

Brands aiming to develop seasonal capsule collections with impactful visuals.

Interior Designers exploring materials for statement soft furnishings.

If your goal is to create a textile product that captures attention through texture, volume, and visual drama, toothbrush yarn is your material of choice.

Conclusion

Toothbrush yarn is a modern fancy yarn that offers a rare combination of tactile appeal, visual boldness, and structural versatility. Whether you are working on fashion collections,this yarn brings a distinct character that’s hard to replicate.

From the runways to living rooms, toothbrush yarn is proving itself as more than a trend—it’s a tool for creative expression.

Related News

Discover more about the latest developments in the yarn industry, explore articles on development trends and innovative technologies, and provide you with more industry insights.

Is Slub Yarn Better for Summer or Winter? Textile Brands: Uses, Benefits, and Seasonal Tips

In modern fashion and textile manufacturing, slub yarn is one of the most popular types of yarn. The slightly uneven thickness of the fabric gives it a natural, handmade look that fits in with current fashion trends. But one question that designers, yarn buyers, and manufacturers often ask is whether slub yarn is better for summer or winter.

Guide to Use Chrysanthemum Yarn for Commercial Knitwear

In the global knitwear market, texture has become one of the most effective ways to differentiate products. Buyers are no longer impressed by basic yarn descriptions such as “soft,” “bulky,” or “hairy.” What really drives B2B purchasing decisions today is whether a yarn can deliver visible texture, stable production performance, and repeatable quality at scale.This is exactly where Chrysanthemum Yarn stands out.

Blended yarns are very important in the modern textile industry because they let you combine the best parts of different fibers while getting rid of their worst parts. When you spin two or more types of fiber together, like cotton with polyester, wool with nylon, or cotton with spandex, you get a blended yarn. This type of yarn has properties that aren’t found in single-fiber yarns.